HKU Engineering Team Achieves Milestone in Diamond Fabrication Innovation

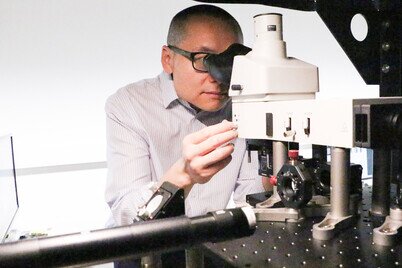

Associate Professor Chu Zhiqin from the Department of Electrical and Electronic Engineering at HKU has made significant strides in diamond technology, showcasing two groundbreaking innovations: cellular force imaging using diamond-based quantum sensing and a revolutionary method for diamond fabrication.

Professor Chu Zhiqin

Quantum Sensing for Cellular Mechanics

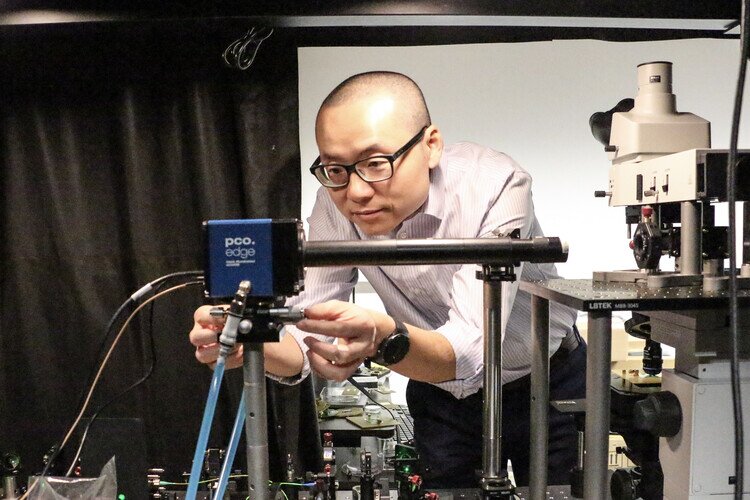

Prof Chu and his research team first unveiled a new technique known as Quantum-Enhanced Diamond Molecular Tension Microscopy (QDMTM) in April 2024. This innovative approach allows for the label-free measurement of cellular forces at the nanoscale, offering a critical tool for biophysics and biomedical engineering.

Traditional methods of measuring cellular forces, such as traction force and molecular tension-based fluorescence microscopy, face sensitivity and data interpretation limitations. These techniques often rely on fluorescent probes, which can suffer from issues like photobleaching, leading to inaccuracies. By integrating NV colour centre-based T1 relaxometry with innovative bio-interface engineering technologies, the QDMTM achieves unprecedented sensitivity and precision in the mechanical and magnetic signal transduction at nanoscales.

The research showcased a novel diamond-based quantum molecular tension probe, elucidating the molecular mechanical interactions between cells and their extracellular matrix. The findings, published in Science Advances, pave the way for a better understanding of cellular interactions and mechanobiology, with potential implications for cancer research and tissue engineering.

Revolutionising Diamond Fabrication

Following this breakthrough, Prof Chu announced the development of an innovative diamond fabrication technology in December 2024. The collaboration, which includes Prof Lin Yuan from HKU and other institutions, including the Southern University of Science and Technology and the Dongguan Institute of Opto-Electronics of Peking University, exemplifies the essence of knowledge exchange in academia. These researchers have accelerated technology development with far-reaching implications by pooling expertise and resources.

An edge-exposed exfoliation method was introduced to facilitate the rapid production of ultrathin and flexible diamond membranes. This technique can produce a two-inch diamond wafer in just 10 seconds, a remarkable improvement over traditional fabrication methods that are often slow and costly.

These ultrathin diamond membranes are compatible with existing semiconductor technologies, making them suitable for various applications, including electronic, photonic, and quantum devices. The inherent properties of diamonds—such as high thermal conductivity, exceptional hardness, and optical transparency—make them ideal for advanced applications in electronics and photonics.

Prof Chu envisions a robust partnership with both academic and industry stakeholders to commercialise this cutting-edge technology. This collaboration is crucial not only for bringing the product to market but also for fostering an ecosystem of innovation that benefits society at large.

Social Impact and Future Applications

The implications of this research extend beyond the academic realm into significant social impact. The ultrathin and flexible diamond membranes can be integrated into next-generation flexible and wearable devices, potentially transforming industries such as healthcare, consumer electronics, and sustainable energy.

For instance, these diamond membranes could be used in advanced medical devices that require high precision and flexibility, enabling better patient outcomes. In sustainable energy, their thermal properties could enhance the efficiency of devices used in electric vehicles and renewable energy systems.

The research team is committed to promoting the use of these high-performance diamond membranes across various sectors, aiming to set a new benchmark in the semiconductor industry. By making this technology accessible, they hope to contribute to advancements that improve quality of life and drive economic growth.

Potential Limitations of the New Fabrication Method

Despite its promising advantages, the new diamond fabrication method may face several limitations. One potential challenge is the scalability of the process for larger wafers or industrial-scale production. While the technology can produce two-inch wafers rapidly, further research is needed to determine if this efficiency can be maintained at larger sizes without compromising quality.

Additionally, the mechanical flexibility of the ultrathin membranes may pose challenges in specific applications that require rigidity. The balance between flexibility and structural integrity must be carefully managed, especially in environments where mechanical stress is a factor.

Commercialisation Plans

Prof Chu and his team are actively seeking partnerships with industry stakeholders to commercialise this groundbreaking technology. Their goal is to promote high-figure-of-merit diamond membranes in various sectors. The research team plans to engage with semiconductor manufacturers and technology firms to explore potential applications and develop products that leverage the unique properties of diamonds.

Moreover, they aim to establish collaborations with academic institutions and research organisations to refine the technology further and identify new market opportunities. By setting a new standard in the semiconductor industry, they hope to accelerate the adoption of diamond materials in commercial products.

Applications Beyond Electronics

The potential applications of the new diamond membranes extend beyond electronics. Their unique properties suggest a variety of uses in fields such as:

- Biomedical Devices: Diamond's biocompatibility and optical transparency make it ideal for medical implants, biosensors, and drug delivery systems.

- Thermal Management: Diamonds’ exceptional thermal conductivity can be utilised in heat spreaders for high-performance computing systems, electric vehicles, and other applications where efficient heat dissipation is critical.

- Optical Devices: The optical transparency of diamond across a broad spectrum makes it suitable for advanced photonic devices, including sensors and lasers for communication technologies.

- Mechanical Applications: The hardness of diamond can be leveraged in cutting tools and wear-resistant coatings, enhancing the durability and performance of various industrial applications.

Conclusion

Prof Chu's recent diamond technology breakthrough highlights diamonds' transformative potential in science and engineering. The advancements in cellular force imaging and the revolutionary fabrication method significantly contribute to fundamental research and practical applications. As these technologies continue to develop, they promise to set new standards in fields ranging from biomedical engineering to advanced electronics, ushering in what Prof Chu describes as the "diamond era."

To read more about Prof Chu’s latest paper, pls click the link below:

https://www.nature.com/articles/s41586-024-08218-x